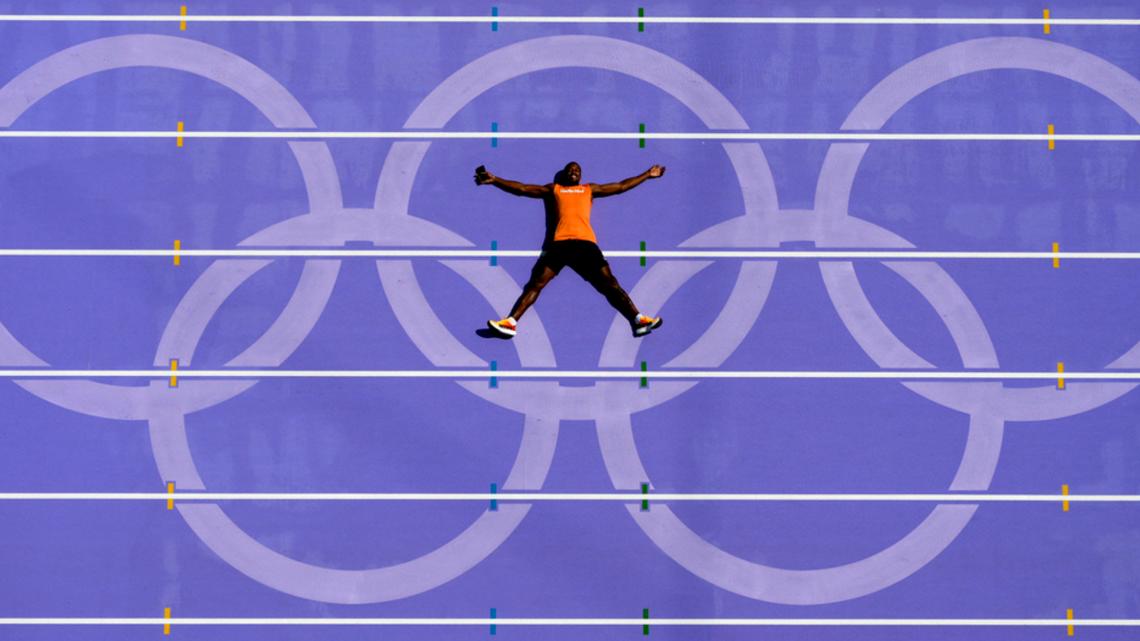

PARIS, France — Track and field gets off to a hot start on Friday, and catching as much attention as the races is the vibrant purple color of the track at the Stade de France.

The two-toned purple track is a break from traditional red, but there are no rules governing the color of the track -- Olympics host countries' organizing committees are free to decide on whatever color they want. Brazil chose a blue track for the 2016 Rio Olympics, the first time a red track hadn't been used at the Summer Games.

Why is the Olympic track purple?

The lighter purple color is for the track itself and competition areas, and the darker purple is for technical areas in the stadium.

Organizers chose purple for a few reasons, but it largely boils down to aesthetics. It's a memorable color that will stand out in photos and be instantly identifiable. The unique choice is also a reflection of France's culture and identity, nodding to the lavender fields of Provence and the country's history of royalty.

Even the glue holding the track down is purple.

The distinctive purple also serves a practical purpose. It provides a high-contrast background for the athletes, making races easier to watch for spectators in the stadium, commentators and television viewers.

A record-setting track?

Will world records fall on another speedy Olympic track? Only time will tell. But it is the mission of every track maker to turn their running surface into the fastest.

Experts at Mondo said they used rubber granules that were more elastic and cohesive to produce the upper layer of the track. In other words, the innovations are meant to enable Olympians to run faster, jump higher and leap further. Kind of like the Olympic motto: “Faster, higher, stronger — together.”

The rest, as always, is up to the athletes.

“It's not the track that's fast, it's the runners who are fast,” Lewis said.

On a fast track three years ago in Tokyo, three world and 12 Olympic records fell.

Purple...and green

Mondo took a sustainable approach when developing this track, incorporating ground up shells from mussels and clams into the surface compound.

The 13,000-square-meter track is made up of 40% recycled materials and renewable resources.